Three 3D Printing Processes Compared - FDM, SLA and MJF

- J Gover

- Nov 6, 2020

- 1 min read

We often get asked, 'which 3D printing process will be best for my part'. Of course, this is as complex subject and it depends on many factors such as budget, functionality, environment, required surface finish and size, to name a few.

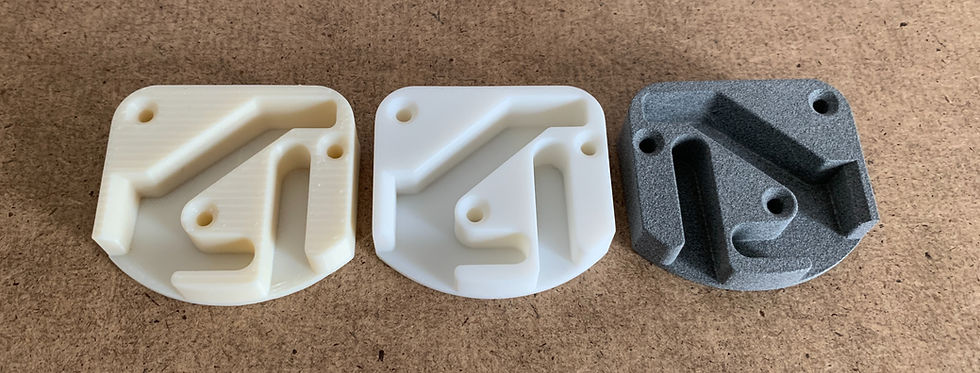

The below images shows a part which was designed to replace a discontinued item for a window, where the customers original part was damaged. We printed the part using three different process to help the customer choose which would be preferred for their application.

The 3 materials and processes used were:

ASA, printed using the FDM process - left

Resin, printed using the SLA process - middle

PA11, printing using the MJF process - right

Because of the angled top face of the part, the FDM process showed some stepping lines, where as the SLA and MJF processes were much smoother. That said, given the application of the part and the exposure to UV light, the customer decided that a UV stable material was critical. In this case we opted for ASA, which is only available using the FDM process. Although the surface finish was not as good, in this case the customer was happy to proceed with FDM.

This brief example highlights how many factors can play a part in material selection, such as external factors like the environment the part will be used in.

We review every part on a case by case basis and will be happy to advise which is most suitable for you. To discuss you requirements, please get in touch at info@printmypart.co.uk

留言